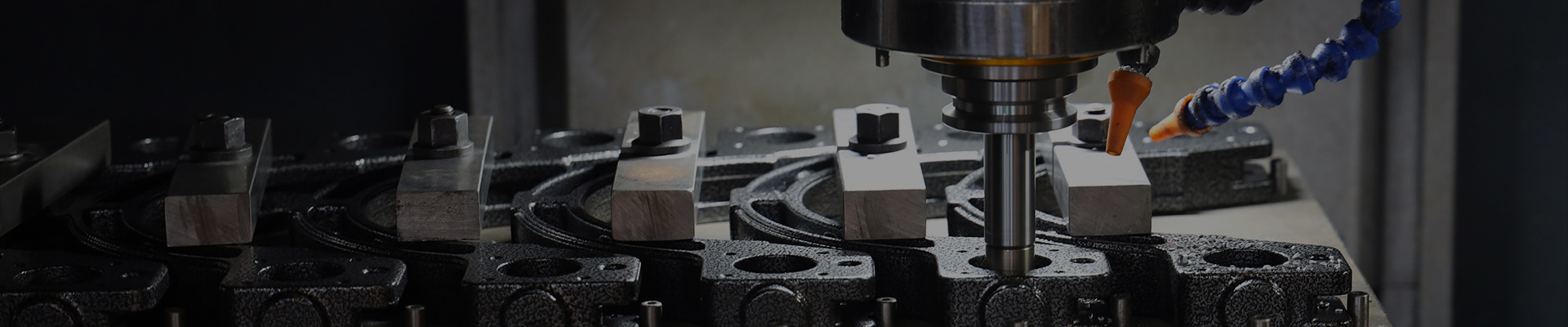

Parts process making and pricing

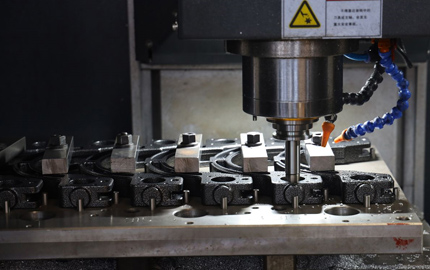

With High-precision Five axis CNC machining center machine tool which already used to process various high-precision tool parts, such as wrench titanium alloy shell, reaction arm, rotary connector, etc. with our technical group,they will assist you determine how great to realize your visio.