Become a Global Expert in Various Solutions for the Sheet Metal Processing Industry

Home / All / Round Duct Making Machine / Auto Spiral Duct Forming Machine /

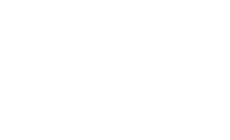

Auto Spiral Duct Forming Machine with High Quality

Auto Spiral Duct Forming Machine with High Quality

Detail Information

Auto spiral duct forming machine Description

spiral round duct forming machine are thin-walled, round, weld-free, air- and water-leak-free ducts made of metal strip rolled into spiral nibbled seams, which are mostly used for air supply and bulk material transport, replacing the traditional white iron ducts (i.e. manually nibbled iron ducts). It is a kind of air duct, with a full mechanism of straight ducts without manual hammering.

Main Technical Parameters

|

Modle

|

Power(kw) |

Diameter | 100-1500mm |

Tube length | 120-8000mm |

Material | Galvanized sheet, stainless steel sheet, aluminum sheet |

Working thickness | 0.4-1mm |

Width | 137-140mm |

Working speed | 1-30m/min |

Locking | Pipe outer surface |

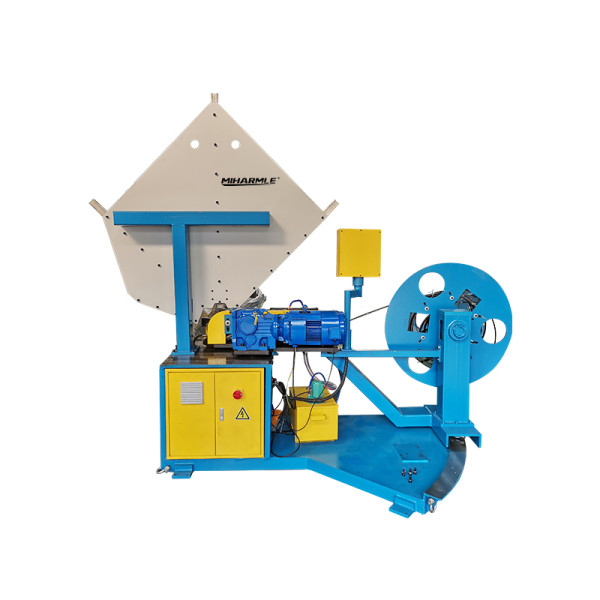

Electronic control system | Computer PLC control, frenquency conversion speed regulation |

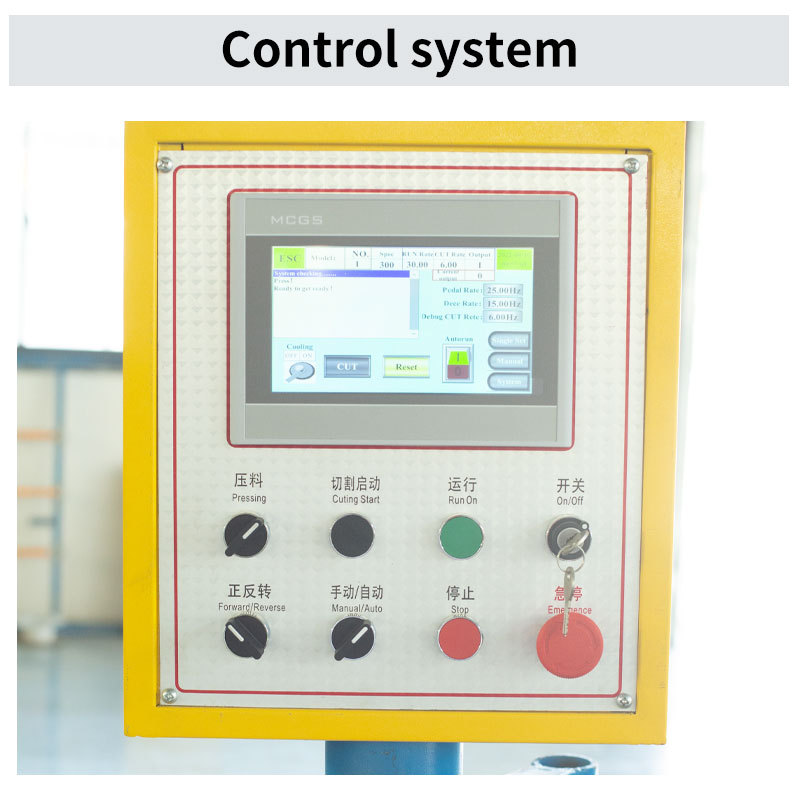

Main motor power | 5.5kw |

Cutting motor power | 4kw |

|

Cutting ways |

Sawblade of cutting

|

Weight | 2200kg |

|

Package size |

2700*1700*2300

|

Machine Details

Precautions

- Safety usage: Before using the Auto Air Duct Production equipment, it is necessary to carefully read and comply with the manufacturer's instructions for use and follow the safety operating procedures of the equipment to ensure personal safety and normal operation of the equipment.

- Maintenance: Regular maintenance of the Auto Air Duct Production equipment is necessary to ensure long-term stable operation. Cleaning and lubricating various parts of the equipment, and replacing worn parts are important maintenance contents.

Review

- Loading...

Please send your message to us

We warmly welcome OEM and ODM orders. Whether selecting a current product from our catalog or seeking engineering assistance for your application, We can meet your any needs in our area . Thank you !

- *Name

- *Tel

- *Title

- *Content